Botou Hengrui Environmental Protection Equipment Co. Ltd.

Single Pulse Bag Filter,Single Pulse Dedusting Device,Pulse Bag Dust Removal Device

Botou Hengrui Environmental Protection Equipment Co. Ltd.

Single Pulse Bag Filter,Single Pulse Dedusting Device,Pulse Bag Dust Removal Device

| Unit Price: | USD 3500 / Set/Sets |

|---|---|

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Min. Order: | 1 Set/Sets |

Model No.: Customized

Structure: Other

Purifying Technology: HEPA

Operating Principle: Active + Passive

Power Source: Electrical

Application Area: Other

Certification: Other

Type: HEPA Filter

Air Volume: >400m³/h

Usage: Industry

Anion Density: Other

Packaging: Wooden box

Transportation: Ocean,Land

Port: Xingang China

Payment Type: L/C,T/T

Incoterm: FOB,CIF

Heng Rui environmental protection - Chinese manufacturers specializes in the production of various industrial dust remover equipment, pulse bag filter, cyclone dust remover, desulfurization and dust remover, boiler special bag dust remover, PL single machine dust remover, dust collection bag, dust skeleton and other dust accessories. The company has strong technical force, strict quality management and high quality after-sales service, won the high praise of the vast number of users both at home and abroad, and in line with the belief of "creating fine products and climbing the peak forever" service to every customer!

The intake discharge part has two forms: one is the standard with bucket type, the other is the open flange.

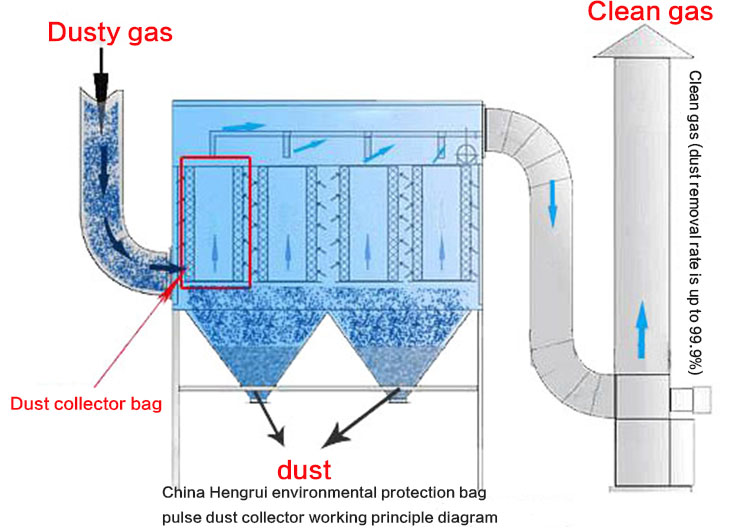

The dust gas is entered into the ash bucket from the intake port or through the open flange mouth into the filter bag. The dust gas is filtered into the net gas chamber through the filter bag, and then through the exhaust port of the air purification chamber, the fan is discharged by the fan. Dust is attached to the outer surface of the filter bag, and the resistance of the bag dust collector is constantly rising. In order to make the resistance of the equipment not more than 1200Pa, the bag dust collector can continue to work, and the dust on the dust collection bag should be cleaned regularly. The ash cleaning is made by the timing sequence of the program controller to start the pulse valve to make the compressed air (0.5~0.7MPa) in the gas package, and the air (called the first wind) is induced by the blowpipe hole (called the first wind) through the venturi tube to induce several times the air around the one wind (called the two wind) into the filter bag for a sudden rapid expansion and shake off the dust with the reverse direction of the air flow. To achieve the purpose of clearing ash.

Botou Heng Rui environmental protection - professional production of DMC single machine bag dust collector manufacturers, the company specializing in the production of various pulse duster, bag type dust remover, stainless steel dust remover, boiler dust remover, Cyclone Dust Collector, wet dust remover and other dust removal equipment and accessories, the products are widely used in oil, chemical, electric power, construction and other projects, Our products are sold at home and abroad, and won the praise and trust of customers.

Product Categories : Single Machine Dust Collector