Botou Hengrui Environmental Protection Equipment Co. Ltd.

FRP Desulphurization Tower,Mine Bag Dust Collector,Asphalt Station Deduster

Botou Hengrui Environmental Protection Equipment Co. Ltd.

FRP Desulphurization Tower,Mine Bag Dust Collector,Asphalt Station Deduster

| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CIF |

| Min. Order: | 1 Set/Sets |

Model No.: Customized

Certification: Other

Noise: 20-40db

Application: Industrial

Control Mode: Other

Usage: Smoke Removal

Packaging: wooden crate

Transportation: Ocean,Land

Port: Xingang China

Payment Type: L/C,T/T

Incoterm: FOB,CIF

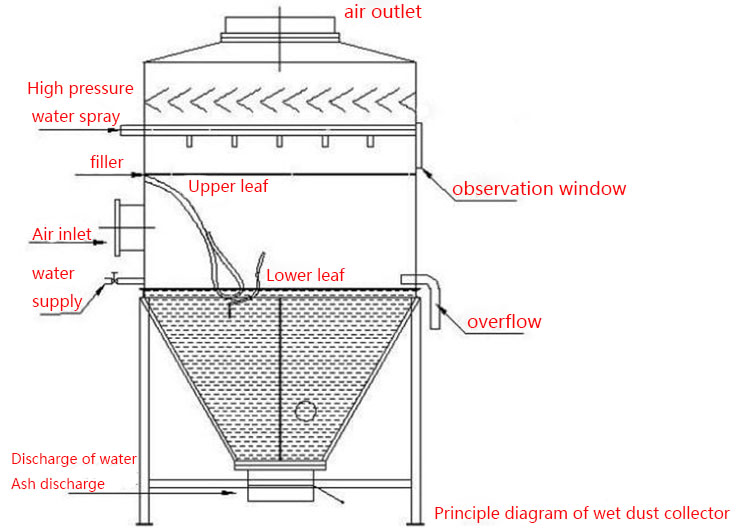

The dust collecting principle of the Wet Electrostatic Precipitator and the dry electrostatic precipitator is the same. The dust is charged by the high pressure corona discharge. The dust after the charge arrives at the dust collecting plate / tube under the action of the electric field force. Dry electrostatic precipitators mainly deal with dry gas with very low moisture content. Wet electrostatic precipitator mainly deals with wet gas with high or even saturated moisture. There is a great difference between WESP and DESP in dust removal on the dust collection board / tube. The dry dust remover usually uses mechanical vibration or sonic dust cleaning to clear the ash on the electrode, while the wet electrostatic precipitator is used regularly to clean the dust with the flow of the scour.

The wet electrostatic precipitator uses the surface of liquid scour to clean the dust on the surface of dust. It can effectively collect fine particles (PM2.5 dust, SO3 acid fog, aerosol), heavy metals (Hg, As, Se, Pb, Cr), organic pollutants (polycyclic aromatic hydrocarbons, dioxin) and so on. The soot emission in wet flue gas can reach 10mg/m3 or even 5mg/m3 after wet electrostatic precipitator. The dust collection performance is not related to the dust characteristics. It is suitable for the treatment of wet flue gas, especially in the treatment of dust smoke after wet desulphurization in power plant and steel plant, but the investment cost of equipment is higher, and it needs to be matched with other dust removal equipment. Use.

Desulphurization rate: 98 (%)

Desulphurization rate: 98 (%)

Dust removal rate: 99 (%)

Resistance loss: 1000 (Pa)

Liquid to gas ratio: 500/800

Dust concentration in export: 300 (g/Nm3)

Use temperature range: 10-80 (c)

Handling air volume: 1000-30000 (m3/h)

Product Categories : Wet Dust Collector Series > Wet Electrostatic Precipitator