Botou Hengrui Environmental Protection Equipment Co. Ltd.

Dust Remover in Chemical Plant,Deduster in Chemical Plant,Industrial Bag Type Dust Collector

Botou Hengrui Environmental Protection Equipment Co. Ltd.

Dust Remover in Chemical Plant,Deduster in Chemical Plant,Industrial Bag Type Dust Collector

| Unit Price: | USD 9800 / Set/Sets |

|---|---|

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Min. Order: | 1 Set/Sets |

Model No.: Customized

Structure: Other

Purifying Technology: Other

Operating Principle: Active + Passive

Power Source: AC Source

Application Area: Other

Certification: Other

Type: HEPA Filter

Air Volume: >400m³/h

Usage: Industry

Anion Density: Other

Packaging: wooden crate

Transportation: Ocean,Land

Port: Xingang China

Payment Type: L/C,T/T

Incoterm: FOB,CIF

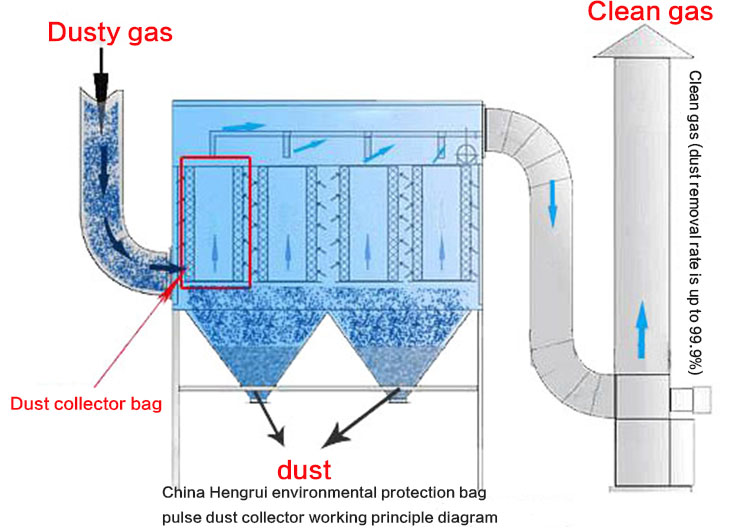

Construction and working principle of DMC single Pulse Deduster

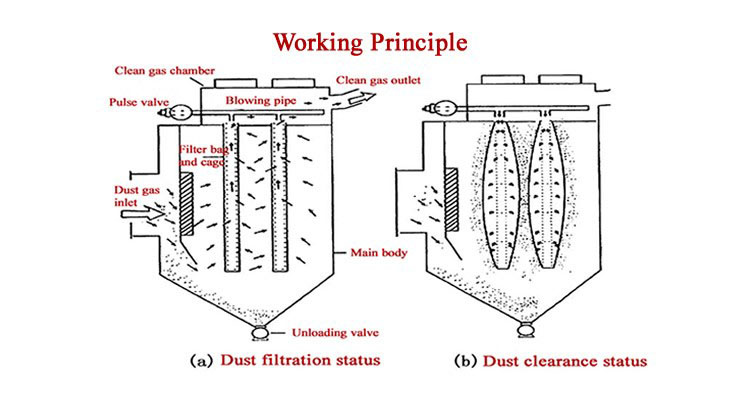

1. Structure of Single Machine Bag Dust Collector

The equipment is mainly composed of the following parts:

Box: including bag chamber, clean gas chamber, perforated panel, filter bag, filter bag skeleton, maintenance door, and box body, designed withstanding voltage 5000Pa.

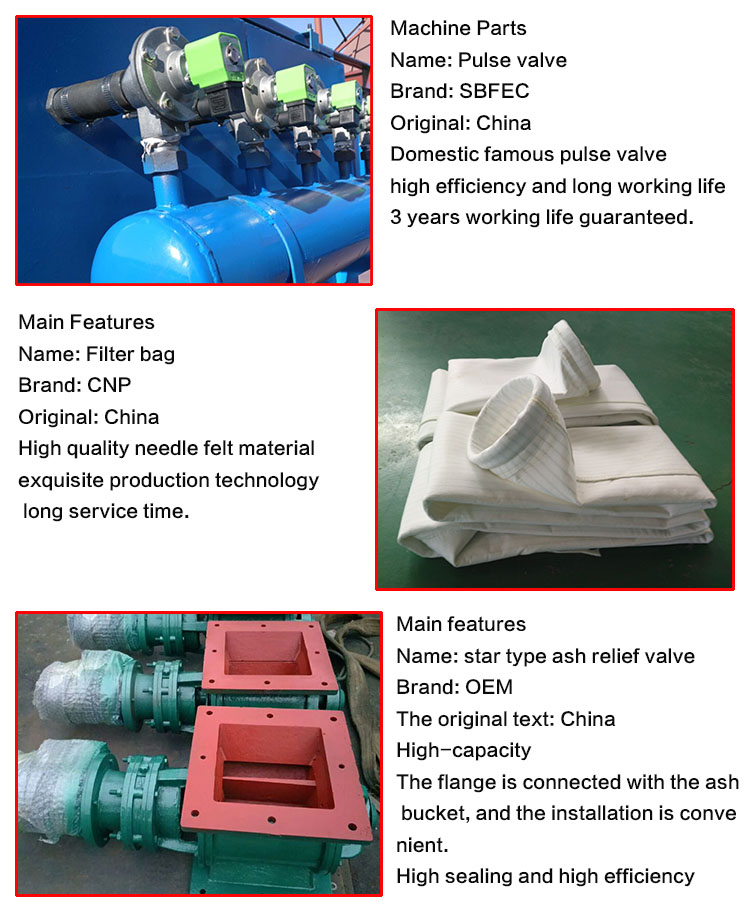

Injection system: including main pipe, blowpipe, pulse valve and control instrument.

There are two forms of air intake and ash discharge: one is the standard belt ash bucket type, the other is the open flange type.

2. The principle of work

The dust gas is entered into the ash bucket from the intake port or through the open flange mouth into the filter bag. The dust gas is filtered into the net gas chamber through the filter bag, and then through the exhaust port of the air purification chamber, the fan is discharged by the fan. Dust is attached to the outer surface of the filter bag, and the resistance of the bag dust collector is constantly rising. In order to make the resistance of the equipment not more than 1200Pa, the bag dust collector can continue to work, and the dust on the dust collection bag should be cleaned regularly. The ash cleaning is made by the timing sequence of the program controller to start the pulse valve to make the compressed air (0.5~0.7MPa) in the gas package, and the air (called the first wind) is induced by the blowpipe hole (called the first wind) through the venturi tube to induce several times the air around the one wind (called the two wind) into the filter bag for a sudden rapid expansion and shake off the dust with the reverse direction of the air flow. To achieve the purpose of clearing ash.

| SPECIFICATIONS FOR 10000 M3/H PULSE JET BAG FILTER | |||

| handling capacity | air volume | m3/h or cfm | 10000 |

| filter rate | m/min | 1.2~1.4 | |

| filter area | m2 | 132 | |

| Main performance parameters | filter bag size | mm | 130 X 2500 |

| filter bag quantity | pc | 132 | |

| pulse valve size | inch | 1.5 | |

| Main performance parameters | pulse valve NO. | pc | 12 |

| ID fan | kw | 18.5 | |

| rotary valve | kw | 0.75 | |

Detailed Images

Main Features

1) Simple structure, easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High efficiency pulse jet cleaning system

4) Installation electric rotary valve, more sealing performance and more efficiency

5) PLC controll and automation

Product Categories : Bag Type Dust Collector Series > Bag-type Dust Remover